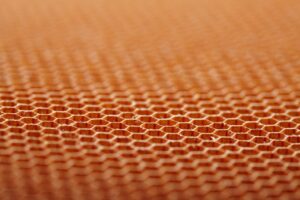

Aramid-acrylic blended pulp is produced by compounding aramid fibers and acrylic fibers in a specific ratio and simultaneously fibrillating them. Blended pulp combines the performance characteristics of both aramid pulp and acrylic pulp, effectively enhancing the comprehensive mechanical properties of products. It provides products with good surface characteristics, dimensional stability, and offers excellent cost-effectiveness.

Dry pulp and wet pulp, with different fiber lengths and fibrillation degrees

High strength, high heat resistance, and high specific surface area

Enhance the comprehensive mechanical properties of products, offering cost-effective advantages by combining the strengths of aramid and acrylic

Aramid / acrylic

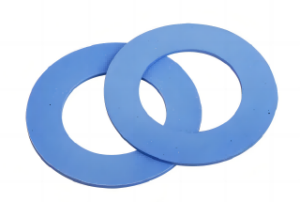

Drive belts / Heavy-duty tries / Reinforced rubber gaskets…

Aramid paper / Spacer paper / Friction paper…

Brake pads / clutch facings

Gaskets

Adhesives / Sealants / Thixctropic gels for coatings…

Engineering plastics

info@sinofibra.com

Telephone

(86) 186 2672 6914

Address

Whether you have any questions or cooperation inquiries, we welcome you to leave us a message.

We will respond promptly and provide answers.

Copyright © Sino Fibra All rights reserved.